平衡机器人,使用带有 BluBug 和 Android 的车轮和 imu 6 轴传感器平衡机器人。

自平衡倒立摆机器人。构建很简单,软件是免费和开源的,基于 Arduino。

自平衡机器人的核心是 IMU,由 3 轴速率陀螺仪、加速度计组成。这 6 个传感器每秒最多采样 1,000 次,并与一段称为 DCM(方向余弦矩阵算法)的代码集成在一起,这是一种结合了每个传感器最佳属性的数学滤波器。机器人的高级代码可以根据平衡的需要简单地询问 DCM 机器人的角度和旋转速率。

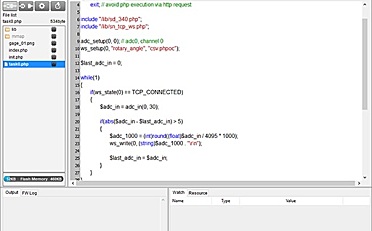

代码区

#include <PID_v1.h>

#include <LMotorController.h>

#include “I2Cdev.h”

#include “MPU6050_6Axis_MotionApps20.h”

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

#include “Wire.h”

#endif

#define LOG_INPUT 0

#define MANUAL_TUNING 0

#define LOG_PID_CONSTANTS 0 //MANUAL_TUNING must be 1

#define MOVE_BACK_FORTH 0

#define MIN_ABS_SPEED 30

//MPU

MPU6050 mpu;

#define OUTPUT_READABLE_YAWPITCHROLL

// MPU control/status vars

#define INTERRUPT_PIN 2 // use pin 2 on Arduino Uno & most boards

#define LED_PIN 13 // (Arduino is 13, Teensy is 11, Teensy++ is 6)

bool blinkState = false;

// MPU control/status vars

bool dmpReady = false; // set true if DMP init was successful

uint8_t mpuIntStatus; // holds actual interrupt status byte from MPU

uint8_t devStatus; // return status after each device operation (0 = success, !0 = error)

uint16_t packetSize; // expected DMP packet size (default is 42 bytes)

uint16_t fifoCount; // count of all bytes currently in FIFO

uint8_t fifoBuffer[64]; // FIFO storage buffer

// orientation/motion vars

Quaternion q; // [w, x, y, z] quaternion container

VectorInt16 aa; // [x, y, z] accel sensor measurements

VectorInt16 aaReal; // [x, y, z] gravity-free accel sensor measurements

VectorInt16 aaWorld; // [x, y, z] world-frame accel sensor measurements

VectorFloat gravity; // [x, y, z] gravity vector

float euler[3]; // [psi, theta, phi] Euler angle container

float ypr[3]; // [yaw, pitch, roll] yaw/pitch/roll container and gravity vector

// packet structure for InvenSense teapot demo

uint8_t teapotPacket[14] = { ‘$’, 0x02, 0,0, 0,0, 0,0, 0,0, 0x00, 0x00, ‘\r’, ‘\n’ };

//PID

#if MANUAL_TUNING

double kp , ki, kd;

double prevKp, prevKi, prevKd;

#endif

double originalSetpoint = 174.29;

double setpoint = originalSetpoint;

double movingAngleOffset = 0.3;

double input, output;

int moveState=0; //0 = balance; 1 = back; 2 = forth

#if MANUAL_TUNING

PID pid(&input, &output, &setpoint, 0, 0, 0, DIRECT);

#else

PID pid(&input, &output, &setpoint, 70, 240, 1.9, DIRECT);

#endif

//MOTOR CONTROLLER

int ENA = 3;

int IN1 = 4;

int IN2 = 8;

int IN3 = 5;

int IN4 = 7;

int ENB = 6;

LMotorController motorController(ENA, IN1, IN2, ENB, IN3, IN4, 0.6, 1);

//timers

long time1Hz = 0;

long time5Hz = 0;

// ================================================================

// === INTERRUPT DETECTION ROUTINE ===

// ================================================================

volatile bool mpuInterrupt = false; // indicates whether MPU interrupt pin has gone high

void dmpDataReady() {

mpuInterrupt = true;

}

void setup()

{

// join I2C bus (I2Cdev library doesn’t do this automatically)

#if I2CDEV_IMPLEMENTATION == I2CDEV_ARDUINO_WIRE

Wire.begin();

Wire.setClock(400000); // 400kHz I2C clock. Comment this line if having compilation difficulties

#elif I2CDEV_IMPLEMENTATION == I2CDEV_BUILTIN_FASTWIRE

Fastwire::setup(400, true);

#endif

Serial.begin(115200);

while (!Serial); // wait for Leonardo enumeration, others continue immediately

// initialize device

Serial.println(F(“Initializing I2C devices…”));

mpu.initialize();

pinMode(INTERRUPT_PIN, INPUT);

// verify connection

Serial.println(F(“Testing device connections…”));

Serial.println(mpu.testConnection() ? F(“MPU6050 connection successful”) : F(“MPU6050 connection failed”));

// wait for ready

Serial.println(F(“\nSend any character to begin DMP programming and demo: “));

while (Serial.available() && Serial.read()); // empty buffer

while (!Serial.available()); // wait for data

while (Serial.available() && Serial.read()); // empty buffer again

// load and configure the DMP

Serial.println(F(“Initializing DMP…”));

devStatus = mpu.dmpInitialize();

// supply your own gyro offsets here, scaled for min sensitivity

mpu.setXGyroOffset(220);

mpu.setYGyroOffset(76);

mpu.setZGyroOffset(-85);

mpu.setZAccelOffset(1788); // 1688 factory default for my test chip

// make sure it worked (returns 0 if so)

if (devStatus == 0)

{

// turn on the DMP, now that it’s ready

Serial.println(F(“Enabling DMP…”));

mpu.setDMPEnabled(true);

// enable Arduino interrupt detection

Serial.println(F(“Enabling interrupt detection (Arduino external interrupt 0)…”));

attachInterrupt(digitalPinToInterrupt(INTERRUPT_PIN), dmpDataReady, RISING);

mpuIntStatus = mpu.getIntStatus();

// set our DMP Ready flag so the main loop() function knows it’s okay to use it

Serial.println(F(“DMP ready! Waiting for first interrupt…”));

dmpReady = true;

// get expected DMP packet size for later comparison

packetSize = mpu.dmpGetFIFOPacketSize();

//setup PID

pid.SetMode(AUTOMATIC);

pid.SetSampleTime(10);

pid.SetOutputLimits(-255, 255);

}

else

{

// ERROR!

// 1 = initial memory load failed

// 2 = DMP configuration updates failed

// (if it’s going to break, usually the code will be 1)

Serial.print(F(“DMP Initialization failed (code “));

Serial.print(devStatus);

Serial.println(F(“)”));

}

// configure LED for output

pinMode(LED_PIN, OUTPUT);

}

void loop()

{

// if programming failed, don’t try to do anything

if (!dmpReady) return;

// wait for MPU interrupt or extra packet(s) available

while (!mpuInterrupt && fifoCount < packetSize)

{

//no mpu data – performing PID calculations and output to motors

pid.Compute();

motorController.move(output, MIN_ABS_SPEED);

unsigned long currentMillis = millis();

if (currentMillis – time1Hz >= 1000)

{

loopAt1Hz();

time1Hz = currentMillis;

}

if (currentMillis – time5Hz >= 5000)

{

loopAt5Hz();

time5Hz = currentMillis;

}

}

// reset interrupt flag and get INT_STATUS byte

mpuInterrupt = false;

mpuIntStatus = mpu.getIntStatus();

// get current FIFO count

fifoCount = mpu.getFIFOCount();

// check for overflow (this should never happen unless our code is too inefficient)

if ((mpuIntStatus & 0x10) || fifoCount == 1024)

{

// reset so we can continue cleanly

mpu.resetFIFO();

Serial.println(F(“FIFO overflow!”));

// otherwise, check for DMP data ready interrupt (this should happen frequently)

}

else if (mpuIntStatus & 0x02)

{

// wait for correct available data length, should be a VERY short wait

while (fifoCount < packetSize) fifoCount = mpu.getFIFOCount();

// read a packet from FIFO

mpu.getFIFOBytes(fifoBuffer, packetSize);

// track FIFO count here in case there is > 1 packet available

// (this lets us immediately read more without waiting for an interrupt)

fifoCount -= packetSize;

mpu.dmpGetQuaternion(&q, fifoBuffer);

mpu.dmpGetGravity(&gravity, &q);

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity);

#ifdef OUTPUT_READABLE_YAWPITCHROLL

// display Euler angles in degrees

mpu.dmpGetQuaternion(&q, fifoBuffer);

mpu.dmpGetGravity(&gravity, &q);

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity);

Serial.print(“ypr\t”);

Serial.print(ypr[0] * 180/M_PI);

Serial.print(“\t”);

Serial.print(ypr[1] * 180/M_PI);

Serial.print(“\t”);

Serial.println(ypr[2] * 180/M_PI);

#endif

input = ypr[1] * 180/M_PI + 180;

}

}

void loopAt1Hz()

{

#if MANUAL_TUNING

setPIDTuningValues();

#endif

}

void loopAt5Hz()

{

#if MOVE_BACK_FORTH

moveBackForth();

#endif

}

//move back and forth

void moveBackForth()

{

moveState++;

if (moveState > 2) moveState = 0;

if (moveState == 0)

setpoint = originalSetpoint;

else if (moveState == 1)

setpoint = originalSetpoint – movingAngleOffset;

else

setpoint = originalSetpoint + movingAngleOffset;

}

//PID Tuning (3 potentiometers)

#if MANUAL_TUNING

void setPIDTuningValues()

{

readPIDTuningValues();

if (kp != prevKp || ki != prevKi || kd != prevKd)

{

#if LOG_PID_CONSTANTS

Serial.print(kp);Serial.print(“, “);Serial.print(ki);Serial.print(“, “);Serial.println(kd);

#endif

pid.SetTunings(kp, ki, kd);

prevKp = kp; prevKi = ki; prevKd = kd;

}

}

void readPIDTuningValues()

{

int potKp = analogRead(A0);

int potKi = analogRead(A1);

int potKd = analogRead(A2);

kp = map(potKp, 0, 1023, 0, 25000) / 100.0; //0 – 250

ki = map(potKi, 0, 1023, 0, 100000) / 100.0; //0 – 1000

kd = map(potKd, 0, 1023, 0, 500) / 100.0; //0 – 5

}

#endif

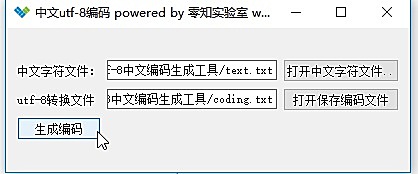

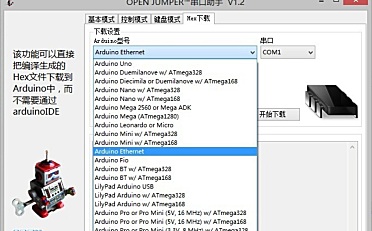

在下面直接下载

基于Arduino UNO的自平衡机器人

22i2复制

没有复制

姿态解算是用DMP么

过期了~大佬